Call:

Showroom

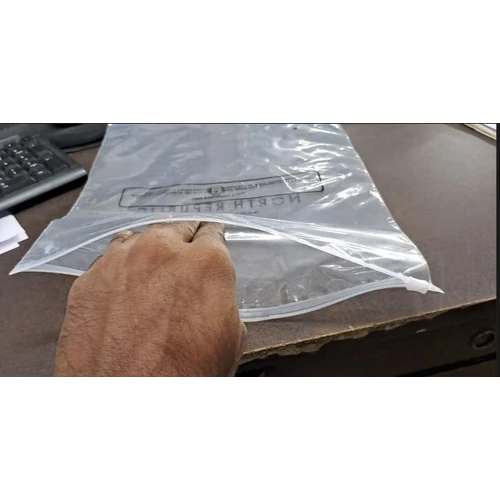

BOPP Tape is typically clear or transparent, making the contents of the package or box it is sealing visible. It is temperature resistant, making it suitable for use in both hot and cold environments. This can be customized with various colors, patterns, and designs to meet specific branding or marketing requirements.

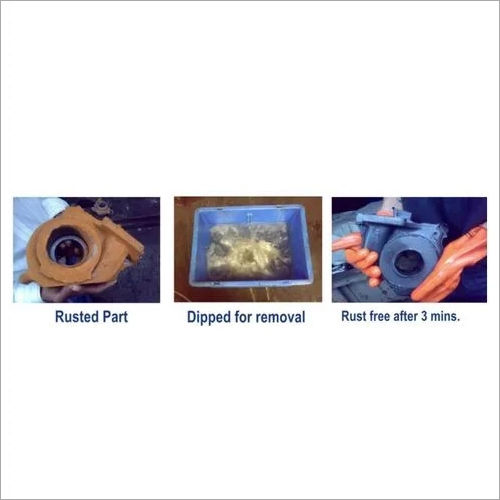

Rust preventive oil is a type of lubricant that is specifically designed to prevent rust and corrosion on metal surfaces. In most cases, they contain additives that form a barrier between the metal surface and the surrounding environment, preventing moisture and other corrosive agents from reaching the metal.

LD Packaging Roll is a type of packaging material. Because of its excellent moisture resistance, durability, and ease of processing, LDPE is a lightweight and flexible material that is commonly used for packaging applications. This comes in a variety of sizes and thicknesses, and they can be customized to meet specific packaging needs.

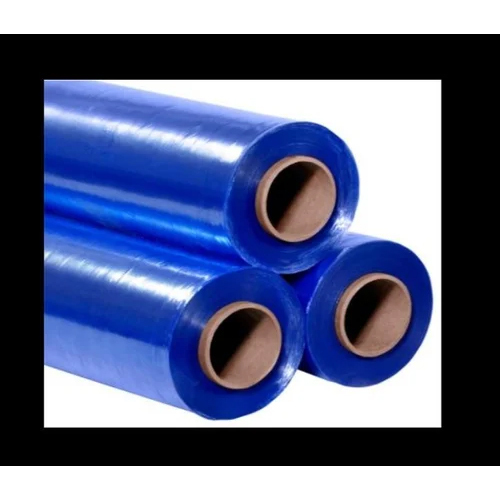

Plastic Stretch Wrap Film is a type of polyethylene resin-based packaging material. It is frequently used to wrap and secure products on pallets or during transportation. Stretching the film around the product and then allowing it to shrink back creates a tight seal around the product.

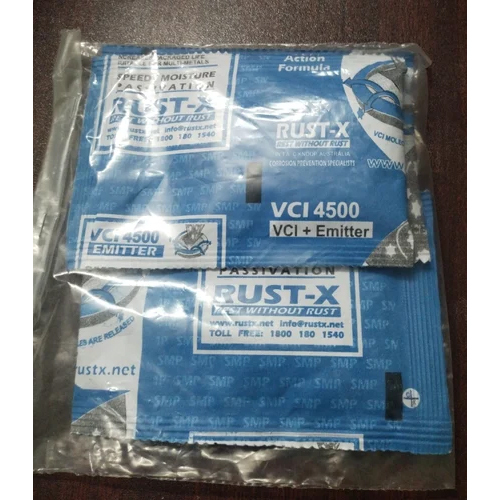

VCI Plastic Films are specifically designed to protect metal products from corrosion. Special chemicals in these films vaporize and form a protective layer on metal surfaces, preventing corrosion. They are commonly used to protect metal components during storage and transportation in industries.

VCI Paper Roll is available in a variety of sizes and thicknesses to meet a variety of packaging needs. VCI paper is non-toxic, making it suitable for use with food and other applications. It is simple to use and can be cut to size for wrapping around metal products.

Send Inquiry

Send Inquiry