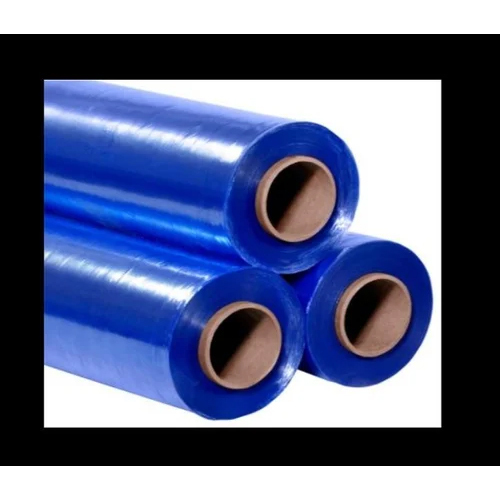

VCI Film Sheets

Price 320 INR/ Kilograms

VCI Film Sheets Specification

- Type

- Stretch Film

- Material

- VCI

- Transparency

- No

- Hardness

- Soft

- Color

- Blue

- Warranty

- 1 Year

VCI Film Sheets Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 1 - 2 Days

- Sample Available

- No

- Main Domestic Market

- Karnataka

About VCI Film Sheets

In terms of metal protection, our VCI Film Sheets are cutting edge. These cutting-edge sheets are used to protect metal parts and machinery from rust, corrosion, and damage while being stored and transported. A corrosion-inhibiting layer is created around metal surfaces thanks to the VCI technology incorporated in the film, successfully protecting them from moisture, impurities, and the environment. Our VCI Film Sheets offer the security and protection that your metal assets deserve, whether you are keeping priceless machinery, expensive auto components, or delicate electronics. Put your faith in our cutting-edge VCI technology to preserve the condition of your investments throughout time.

Specification

|

Thickness |

2 mm |

|

Material |

VCI Plastic |

|

Transparency |

70 % |

|

Color |

Blue |

|

Pattern |

Plain |

|

Packaging Type |

Roll |

|

Usage/Application |

Industrial Use |

Advanced Corrosion Protection

VCI Film Sheets leverage innovative VCI technology to safeguard metal components from rust and corrosion by emitting protective vapors that form an invisible shield. Suitable for ferrous and non-ferrous metals, these film sheets are ideal for long-term storage and overseas shipping, where humidity and environmental factors often pose serious risks.

Soft yet Durable Design

Despite their soft feel, these VCI stretch films deliver robust barrier properties, minimizing moisture, dust, and airborne contaminants. The blue, non-transparent appearance provides an extra layer of privacy and makes it easy to identify packed goods during handling and transportation.

FAQs of VCI Film Sheets:

Q: How do VCI Film Sheets work to prevent corrosion on metal goods?

A: VCI (Volatile Corrosion Inhibitor) Film Sheets release specialized vapors that adhere to metal surfaces, forming a molecular barrier. This barrier blocks moisture and other corrosion-causing agents, preserving metal items throughout storage and shipment.Q: What are the recommended steps for using VCI Stretch Film Sheets?

A: To use the VCI Film Sheets effectively, wrap them securely around clean, dry metal components. Ensure complete coverage and minimal air gaps for optimal corrosion protection. The film can be stretched and layered to fit various shapes and sizes.Q: When should I choose VCI Film Sheets over standard stretch films?

A: Select VCI Film Sheets when your packaging involves metal items that may be susceptible to rust or corrosion, especially during long-term storage or export. They outperform standard stretch films by providing active corrosion protection.Q: Where are VCI Film Sheets commonly used in India?

A: These sheets are commonly utilized across manufacturing units, exporters, warehouses, and logistics companies in India, wherever robust metal goods need secure and corrosion-free packaging for handling, storage, or transit.Q: What are the main benefits of using VCI Film Sheets for industrial packaging?

A: VCI Film Sheets offer peace of mind by ensuring corrosion prevention, reducing maintenance and replacement costs, and simplifying the packaging process. Their soft material avoids scratching surfaces while delivering strong vapor protection.Q: How long does the protection from VCI Film Sheets last?

A: Our VCI Film Sheets provide continuous corrosion protection for up to 12 months under recommended storage and handling conditions. The integrated VCI technology ensures enduring effectiveness throughout the warranty period.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VCI Plastic Category

VCI 3D Plastic Bag

Price 30 INR / Piece

Minimum Order Quantity : 100 Pieces

Type : Other, Packaging Bag

Thickness : 80120 Microns

Width : Customizable

Size : Customizable as per requirement

VCI Packaging Bag

Price 2 INR / Piece

Minimum Order Quantity : 200 Pieces

Type : Other, AntiCorrosion Packaging Bag

Thickness : 50150 microns

Width : Up to 1500 mm

Size : Custom Sizes Available

Plain VCI Films

Price 320.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Type : Other

Thickness : 100 Meter

Width : 1 Meter (m)

Size : 1 MTR

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry