VCI 3D Plastic Bag

Price 30 INR/ Piece

VCI 3D Plastic Bag Specification

- Type

- Packaging Bag

- Tensile Strength

- High (specific values on request)

- Working Temperature

- -20C to +60C

- Density

- 0.92 Gram per cubic centimeter(g/cm3)

- Length

- Customizable

- Width

- Customizable

- Thickness

- 80-120 Microns

- Transparency

- Transparent

- Hardness

- Soft

- Size

- Customizable as per requirement

- Shape

- 3D Gusseted (Fits over parts or pallets)

- Chemical Resistance

- Excellent - Suitable for industrial use

- Closure Type

- Open/Seal Type (subject to order requirements)

- Standards

- Meets international packaging norms

- Application

- Protection and packaging of metal components and machinery

- Surface Finish

- Smooth

- Storage Life

- Up to 24 months in original packing

- Anti-Corrosion Property

- VCI (Volatile Corrosion Inhibitor) embedded

- Printability

- Yes, can be custom printed

VCI 3D Plastic Bag Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 - 2 Days

- Main Domestic Market

- Karnataka

About VCI 3D Plastic Bag

Our VCI 3D Plastic Bag is the best option for securing your priceless metal components during storage and shipping. This cutting-edge bag is expertly constructed and created to offer complete corrosion protection. It encloses your metal things in a three-dimensional shield to keep them rust-free even in harsh situations. By using our VCI 3D Plastic Bag, you not only safeguard your metal assets but also lessen the demand for surplus packaging supplies, promoting a more environmentally friendly and sustainable method.

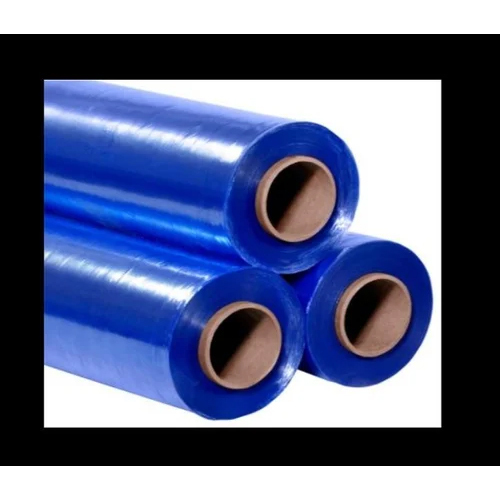

Specification

|

Thickness |

2 mm |

|

Material |

VCI Plastic |

|

Transparency |

70 % |

|

Color |

Blue |

|

Pattern |

Plain |

|

Packaging Type |

Roll |

|

Usage/Application |

Industrial Use |

Reliable Anti-Corrosion Solution

Engineered with VCI technology, these 3D gusseted plastic bags offer advanced protection for metal items by releasing corrosion-inhibiting molecules, guarding contents during storage and transit. Their strong tensile strength and excellent chemical resistance ensure durability even under challenging industrial conditions.

Customizable for Varied Needs

Available in customizable sizes and shapes, these bags can be tailored to fit specific parts or pallets. Choose between open or seal-type closures as per your requirements, and benefit from optional custom printing for branding or labeling purposesmaking logistics and identification seamless.

Long-Lasting Industrial Performance

Purpose-built for harsh environments, the bags function effectively within a wide temperature range of -20C to +60C. The smooth surface finish aids in easy handling, and compliance with international packaging norms ensures suitability for global supply chains. Their robust storage life and reliable protection contribute to cost and operational efficiency.

FAQs of VCI 3D Plastic Bag:

Q: How does VCI technology prevent corrosion for packaged metal parts?

A: VCI (Volatile Corrosion Inhibitor) technology releases vapor-phase corrosion inhibitors that settle on metal surfaces, forming an invisible protective layer to prevent rust and corrosion while the item is stored or shipped within the 3D plastic bag.Q: What customization options are available for the size and printing of these bags?

A: Sizes can be fully customized in both length and width as per your specifications. Additionally, the transparent surface of the bag allows for custom printing to display branding or handling information as required.Q: When should I use a seal-type closure versus an open closure?

A: Seal-type closures are recommended when a dust-tight or moisture-controlled environment is crucial, while open closures are suitable for applications where frequent access or additional ventilation is needed. Clients can choose the closure type based on their order requirements.Q: Where are these bags typically used within industry?

A: These gusseted bags are used across various industries for packaging, storing, and transporting metal components and machinery, especially where corrosion prevention during transit or storage is critical.Q: What is the process for storing items using these VCI 3D bags?

A: Simply place the cleaned and dry metal part or equipment inside the gusseted bag, ensuring full coverage. For added protection, seal the bag as per your closure selection. Proper use extends the storage life up to 24 months with continuous anti-corrosion benefits.Q: What are the main benefits of using these VCI plastic bags for industrial packaging?

A: The bags provide superior chemical resistance, adapt to various item sizes, and offer high tensile strength, ensuring safe handling. The VCI property prevents corrosion, and customizable features enhance operational flexibility, while international compliance supports export and supply chain requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VCI Plastic Category

VCI Packaging Bag

Price 2 INR / Piece

Minimum Order Quantity : 200 Pieces

Color : Blue

Material : Other

Type : Other, AntiCorrosion Packaging Bag

Hardness : Soft

Plain VCI Films

Price 320.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : Blue

Material : VCI Plastic

Type : Other

Hardness : Soft

VCI Film Sheets

Price 320 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : Blue

Material : VCI

Type : Stretch Film

Hardness : Soft

VCI Plastic

Price 320 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : Blue

Material : Plastic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry